Making a trip to a Pet Store these days reveals how much the Pet Food industry has evolved over the past two decades. Previously, pet owners only had the choice between a few major brands and several life cycle formulations to feed their four-legged friends. Today, making the choice of what to feed cats and dogs means picking between hundreds of brands and recipes.

From foods made up of standard and exotic proteins to various health additives, grains, and even formulas adapted to very specific life stages, activity levels, and individual breeds; the choices are almost endless. Furthermore, each can or bag of pet food distributed and sold in the US and Europe has a set of particular nutritional specifications on the label, requirements that must be met by all pet food manufacturers.

Generally, most regulations stipulate that pet foods are required to disclose the minimum proportion of crude fat and crude protein in a diet, along with the maximum proportion of crude fiber and moisture (water). Additionally, manufacturers must publish the maximum amount of ash each recipe contains. These requirements indicate the major components of a diet where fat and protein, in general, add nutritional value to the feed while fiber, moisture, and ash do not.

Therefore, all pet food manufacturers are challenged with operating plants as efficiently as possible and retaining a focus on product quality while keeping costs in check – this can be a difficult task by any measure in today’s economy. Typically, analytical tests to examine raw materials, intermediates, and finished products can consume plenty of production hours with increasing costs for reagents and consumable items. Sites lacking on-site analytical laboratories could be required to send samples to outside laboratories, which means obtaining results can take days. These delays can significantly impact plant efficiency if the product is to be held in quarantine until the completion of the necessary tests.

For over 40 years, the use of near-infrared (NIR) technology has been established in the food, feed, and agriculture industries as a way to test for properties such as protein, fiber, fat, moisture, ash, amino acids, and more. NIR testing is accurate, safe, and fast (analysis in seconds). Furthermore, NIR requires minimal sample preparation with no reagents, it is generally non-destructive, and can also be configured for the analysis of solids, liquids, slurries, oils, and suspensions. Accuracy is often analogous to the wet chemical methods that it replaces. Yet, NIR precision is almost always superior.

What is NIR Analysis?

Near-infrared (NIR) uses diffusely reflected light in the 800 to 2500 nanometer (nm) range to analyze a sample and was first developed as a technique for predicting the chemical composition of a wide range of unknown samples. Respectively, NIR light affects the molecular bonds of C-H, N-H, and O-H: bonds that directly correspond to the sample constituents of interest, such as protein, fat, fiber, moisture, sugar, starch, and amino acids, to name a few.

When NIR light interacts with a sample, the light is partly absorbed while in part diffusely reflected. The amount of absorbed light, at a particular wavelength, is immediately proportional to the concentration of the constituent of interest. In other words, the more considerable the NIR light is absorbed in a particular wavelength means the greater presence of a constituent (protein, moisture, fat, etc.) in the sample.

A sequence of standard samples of known concentration, examined using a high accuracy reference technique, is scanned to calculate the absorbance values at wavelengths throughout the NIR region. Then, by using one of several mathematical models to correlate the reference lab values to the amount of absorbed NIR energy calibration is then established. The calibration can then be put to use to determine the constituent concentration of unknown samples.

Where Can NIR Be Used for Pet Food Manufacturing?

Throughout processing plants, NIR can be situated in numerous locations so that incoming raw materials can be thoroughly tested to validate the integrity of a given supplier. Raw materials can also be tested to control meal composition, ensure adequate ration supplementation, and optimize a cost-effective formulation. NIR facilitates the immediate verification of the compliance of incoming raw materials, thus eliminating the costly step of confining material in quarantine. Non-compliant raw materials can be rejected or manufacturers can insist on a reduction of the contracted price.

NIR can also be used to inspect in-process and finished products. Testing at the mixer can optimize the process by limiting the introduction of liquid fat and other materials, including expensive items, such as enzymes, amino acids, and organic acids. NIR can be installed at the extruder and dryer to determine moisture levels as well as being fitted at the oil sprayer to prevent blockages and monitor fat levels. The finished product can be analyzed to verify and document label claims. With NIR, 100% analysis rates of all finished products are possible, providing traceability for every shipment that leaves the plant.

What is the Cost Justification for Using NIR?

NIR provides excellent payback for pet food manufacturers, this is due to the fact NIR ensures consistent quality in manufacturing and a reduction in re-work costs.

- Verification of raw material suppliers ensures they are providing high-quality materials and claims filed if contract specifications are not met.

- Optimal use of expensive ingredients facilitated by the least-cost formulation while safeguarding nutritional goals.

- Precise control of final product moisture ensures optimal shelf life and maximum yield for reduced costs and increased profits.

- Rapid analysis reduces the cycle time and helps to increase the efficiency of the plant.

The Unity Scientific® Pet Food Analyzer Featuring the SpectraStar 2600XT

The Unity Scientific SpectraStar 2600XT is a full scanning NIR monochromator system designed for the food, feed, and agricultural industries.

SpectraStar XT has incorporated patented TAS (True Alignment® Spectroscopy) technology to align instruments to distinct factory specifications. Provided with every instrument is a set of standards that run in the factory and then run at install. Therefore, TAS can then be initiated at any time (usually after a lamp change or service event) which realigns the instrument back to factory specification. This makes it certain that the instrument is always calibrated at factory specification and removes any drift in your calibration results that are attributed to the instrument.

The Unity Pet Food Analyzer comes equipped with everything needed to get started. Included in the package is the SpectraStar 2600XT, all sample cups and accessories, and calibrations for ingredients and dry pet food. The calibration for dry pet food comes with the requisite constituents for protein, fat, fiber, moisture, and ash: if further constituents are required they are made available through independent calibration provider – Aunir.

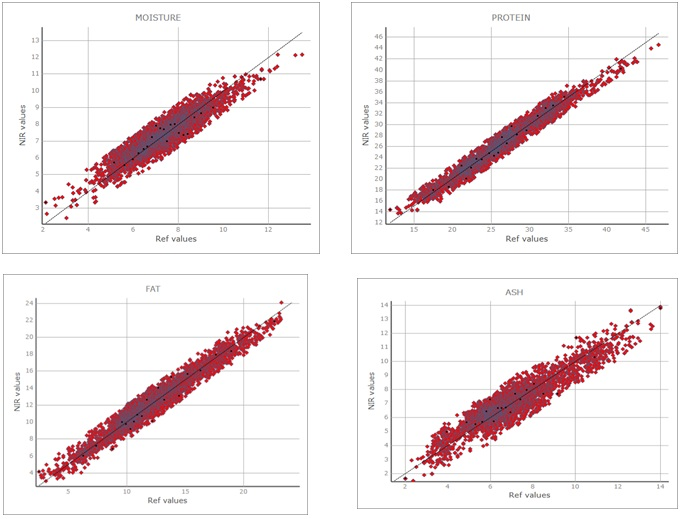

Typical Results of Using the Unity Scientific SpectraStar 2600XT NIR Analyzer for Pet Food Analysis

Results of calibration for a wide-range assortment of finished dry pet food – includes multiple formulas in a single calibration.

Table 1.

| Property | Range | Standard Error of Prediction |

|---|---|---|

| Moisture | 4.0 - 12% | 0.20 |

| Fat | 6.0 – 25% | 0.40 |

| Protein | 20 – 42% | 0.70 |

| Ash | 5.0 – 12% | 0.50 |

Easy to Optimize Performance

Guaranteed to be accurate, the SpectraStar 2600XT is a next-generation state-of-the-art monochromator system with an optimum wavelength range of 1100-2600 nm. This range incorporates the primary bands of C-H, N-H blends, and O-H bonds found in all major constituents such as protein, fat, moisture, starch, fiber, amino acids, carbohydrates, and sugar. By utilizing the longer wavelengths from 1800-2400 nm there is an improvement of sensitivity, accuracy, and signal to noise ratio which results at low concentrations. This wavelength range is essential to testing and determining levels of sugars, amino acids, starch, fiber, and ensuring low levels of protein and fat.

Easy to Implement

Unity has reduced the burdening cost of NIR utilization. Calibration transfer is made easy due to systems being factory-matched. Installations are uncomplicated while the operation is straightforward, yet flexible for customization. Maintenance has been simplified for efficiency.

The SpectraStar 2600XT has been designed with operators of all skill levels in mind. The system is controlled by UScan which is easy to use database-driven software. Training operators to use the system can be done in 15 minutes. Customization of data management and reporting is possible for ultimate flexibility. The configuration is simply designed to support numerous individual recipes with unique constituent limits while monitoring and validation requirements are made simple.

How Does Unity Scientific Deliver Value in NIR Analysis for the Pet Food Plant?

Every laboratory and process control investment must produce swift, predictable business values due to the increasing pressures of generating a profit and meeting the demands for cost control.

The Unity Scientific Pet Food Analyzer is a superior analytical solution for the pet food industry. From raw materials to finished products; the rapid testing capability of the SpectraStar is perfect for analyzing protein, moisture, fat, ash, fiber, and many more in all aspects of the pet food plant.

This information has been sourced, reviewed and adapted from materials provided by Unity Scientific.

For more information on this source, please visit Unity Scientific.

August 17, 2020 at 01:50PM

https://ift.tt/3iNL9FQ

How to Satisfy Label Requirements in Pet Food Production - AZoM

https://ift.tt/3fbzbE8

Bagikan Berita Ini

0 Response to "How to Satisfy Label Requirements in Pet Food Production - AZoM"

Post a Comment